- Sauer Danfoss Hydraulic Pump Manuals

- Sauer Danfoss 90 Series 75cc Pump Parts Manual

- Sauer Danfoss M46 Pump Parts Manual

- Sauer Danfoss Pump Catalog

Free Download Manual: Sauer Danfoss Series 90 Axial Piston Pumps – Technical Data, Specifications & Features – Full PDF.

Sauer Danfoss Hydraulic Pump Manuals

FREE MANUAL FOR HEAVY EQUIPMENT PROFESSIONALS – LEARNING

Series 90 Axial Piston Pumps, Technical Information, Revisions, History of Revisions, Table of Revisions, Changed, Correct Shaft Torque Rating Information, Corrections to Nut Torque for Tapered Shaft, Edits to the Specifications, And Model Code, Other Edits, Minor Edits and Dimension Changes, Series 90 Family of Pumps and Motors, Series 90 – Advanced Technology, Seven Sizes of Variable Displacement Pumps, Proven Reliability and Performance, Compact, Lightweight, Worldwide Sales and Service, Series 90 Variable Displacement Pumps, Series 90 Motors, PLUS+1 Compliant Controls and Sensors, Design, Series 90 Pump Cross-Section, Slider Block, Servo Piston, Piston, Servo Arm, Slipper, Displacement Control, Bushing, Cylinder Block, Cradle Bearing, Valve Plate, Roller Bearing, Rear Bushing, Input Shaft, Charge Pump, SwashPlate, Cradle Guide, Typical Name Plate, Model Code, Serial Number, Place of Manufacture, Control Handle, Displacement Control Valve, Reservoir, Vacuum Gauge, Purge Relief Valve, Fixed Displacement Motor, Pump SwashPlate, Servo Control Cylinder, Loop Flushing Valve, Motor SwashPlate, System Schematic, General Specifications, Direction of Rotation, Pipe Connections, Recommended Installation Position, Features and Options, Feature, Flow at Rated Speed, Torque at Maximum, Mass Moment of Inertia of Rotating Components, Weight, Rotation, Main Ports, Main Port Configuration, Case Drain Ports, Other Ports, Shafts, Operating Parameters, Parameter, Input Speed, Minimum, Rated Speed, Operating Parameters, Fluid Specifications, Feature, Viscosity, Temperature Range, Filtration (Recommended Minimum), Overview, Input Speed, Minimum Speed, Rated Speed, Maximum Speed, Independent Braking System, System Pressure, System Pressure, Application Pressure, Maximum Working Pressure, System Pressure (Continued), Minimum Low Loop Pressure, Servo Pressure, Charge Pressure, Minimum Charge Pressure, Maximum Charge Pressure, Minimum Charge Inlet Pressure, Maximum Charge Pump Inlet Pressure, Case Pressure, Rated Case Pressure, Auxiliary Pad Mounted Pumps, External Shaft Seal Pressure, Temperature and Viscosity, Temperature, Maximum Intermittent Temperature, Minimum Temperature, Viscosity, Recommended Range, Filtration System, System Design Parameters, Filtration Options, Charge Pressure Filtration (Partial Charge Pump Flow), Technical Data According to ISO 16889, Remote Charge Pressure Filtration, Charge Pressure Filtration, Screen, Hydraulic Fluid Reservoir, Charge Pump, To Pump Case, Fluid Selection, Reservoir, Case Drain, Pump Life, Charge Pump, Charge Pump Sizing, Selection, Continuous Operation at Low Input Speeds, High Shock Loading, High Flushing Flow Requirements, Multiple Low Speed High Torque Motors, High Input Shaft Speeds, Bearing Loads and Life, Applications with External Shaft Loads, Understanding and Minimizing System Noise, Fluid-Borne Noise, Structure Born Noise, Sizing Equations, Mounting Flange Loads, Overhung Load Example, Series 90 Master Model Code, Type and Rotation, Controls, High Pressure Regulation, Auxiliary Mounting Pad, End Cap Ports, Filtration, Displacement Limitation, Shaft Options, Charging System, Series 90 Master Model Code, High Pressure Setting A, High Pressure Setting B, Charge Pressure Setting, Solenoid Connector, Pump Displacement VS. Electrical Signal, Solenoid Data, Response Time, Control Options, Electric Displacement Control (EDC), Options KA, KP, KT, Features and Benefits, Electric Displacement Control Schematic, Cross-Section, Control Options, Electric Displacement Control (EDC) (Continued), Electrical Characteristics, Control Signal Requirements, MS Connector, Deutsch DT Series Connector, Control Options, Response Time, Pump Output Flow Direction VS. Control Current, EDC Using a Dual Coil in Series, Manual Over Ride (MOR), EDC Pilot Stage (PCP), EDC Second Stage, Unintended MOR Operation Will Cause the Pump to Go Into Stroke, Control Options, Hydraulic Displacement Control (HDC), Option HF, Features and Benefits of the Hydraulic Displacement Control, Pump Returns to Neutral, Hydraulic Displacement Control Schematic, Cross-Section, Manual Displacement Control (MDC), Options Ma, MB, Features and Benefits of the Manual Displacement Control, Manual Displacement Control Schematic, Cross-Section, External Control Handle Requirements, MDC Handle Rotation Parameters, MDC with Neutral Start Switch (NSS), Non Feedback Proportional Electric Control (NFPE), Input Signal Requirements, Multi-Function Valves, Overpressure Protection, Pressure Limiting Function, To Control, Servo Piston, Bypass Hex Adjustment, Servo Piston, Multifunction Valve, Bypass Function, Auxiliary Mounting Pads, Mating Pump Requirements, Auxiliary Pump Mounting Flange and Shaft, Auxiliary Pump Dimensions, Displacement Limiter, Displacement Limiter Location, Shaft Torque, Shaft Torque and Spline Lubrication, Shaft Torque for Tapered Shafts, Shaft Availability and Torque Ratings, Charge Pump, Charge Pump Output Flow, Charge Pump Power Requirements, Features and Options, Speed Sensor, Electrical and Environmental Data, Electrical, Supply Voltage, Maximum Operating Current, Required Current, Output Voltage in Low State, Maximum Frequency, Peak Reverse Voltage, Operating and Storage Temperature, Features and Options, Connector Pin Assignments, Ground, Installation Drawings, Manual Displacement Control (MDC), Frame Size 055, Auxiliary Mounting Pad – Options AB, BC, CD, BB, Shaft Dimensions, Frame Size 075, Manual Displacement Control Handle Dimensions, Frame Size 075 NFPE Options FK, FL, FM, FN, Multifunction Valve, System Pressure, Coupling Must not Protrude Beyond this Surface, Shaft Dimensions, Control MDC, Option Ma, Manual Displacement Control Handle Dimensions, Frame Size 100, Undercut Diameter, Full Spline, Major Diameter, Pitch Diameter, Length, Pressure Angle, Frame Size 130, Frame Size 180, Frame Size 250, Cover Plate, 3-POSITION (F-N-R) Electric Control, Dimensions, Electric Displacement Control (EDC) with MS-Connector or Packard Connector, Hydraulic Displacement Control (HDC), Manual Displacement Control (MDC) with Neutral Start Switch, Electro hydraulic Displacement Control (NFPE) (Except 075 NFPE), Integral Pressure Filter, Remote Pressure – Without Filter…

- Pages: 88

- Size: 3.48 MB

- Format: PDF (Adobe Reader)

- Contenido: Manual for Sauer Danfoss Series 90 Axial Piston Pumps – Technical Information, Description, Specifications, Operating Parameters, System Design Parameters, Master Model Code, Control Options, Features, Options & Installation Drawings – Information

MANUAL – SAUER DANFOSS SERIES – AXIAL PISTON PUMPS – TECHNICAL INFORMATION – DESCRIPTION – SPECIFICATIONS – OPERATING PARAMETERS – SYSTEM DESIGN PARAMETERS – MASTER MODEL CODE – CONTROL OPTIONS – FEATURES – OPTIONS – INSTALLATION DRAWINGS

Sauer Danfoss 90 Series 75cc Pump Parts Manual

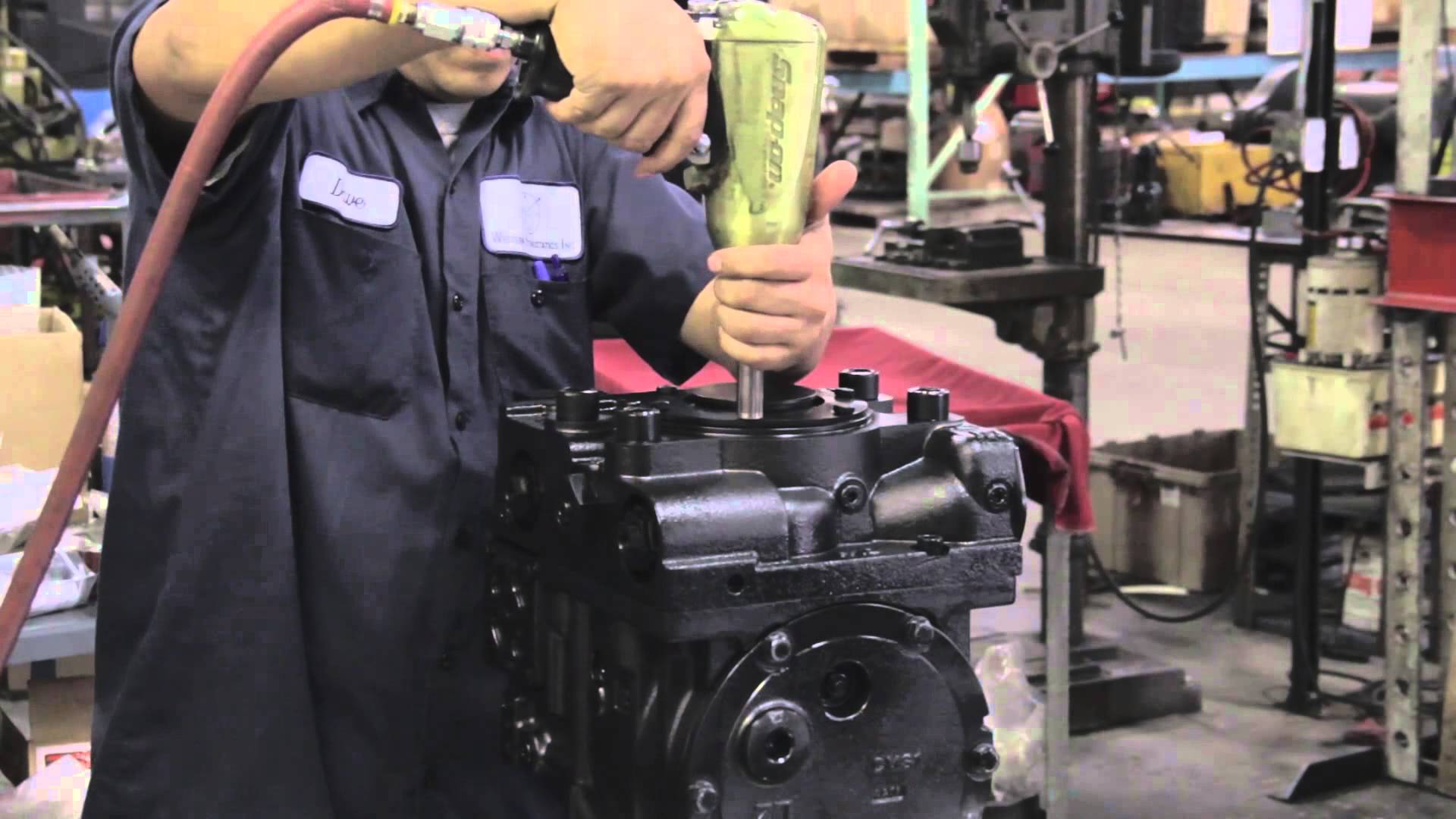

The Sauer-Danfoss model number is used by the factory in manufacturing. On repeat orders, a complete unit can be ordered by the model number. Model Code The Sauer-Danfoss model code completely defines the specific unit and must be used when ordering parts to service this product. Serial Number The Sauer-Danfoss serial number is used to. Series 90 hydraulic pump and motor can be applied together or combined with other products in a system to transfer and control hydraulic power. They are intended for closed circuit applications. Series 90 pumps can be used together in comb ination with other Sauer-Danfoss pump and motor in the overall hydraulic system.

Sauer Danfoss M46 Pump Parts Manual

Tags: manual, manuals, learning, books, instructions, file, book, document, free, instructionals, downloading, data, instructors, infos, learn, free, information, download, sauers, danfosses, series, axials, pistons, pumps, technicals, informations, descriptions, specifications, operating, parameters, systems, designs, parameters, masters, models, codes, controls, options, features, options, installations, drawings, learning, downloadsService Parts Manual Axial Piston Pumps and Motors, Series 18 BN-2-41635 520L0664 Rev BA Feb 2014 5 General information Date code The date code is defined as the year and week of manufacture. The same item number may list more than one part number. The Sauer-Danfoss model code completely defines the specific unit and must be used when ordering parts to service this product. Model number The Sauer-Danfoss model number is used by the factory in manufacturing. On repeat orders, a complete unit can be ordered by the model number. Serial number The Sauer-Danfoss serial number is used to.